MENU

-

Products

Double mag clamp MGW

(Magnetic clamp)

It is magnetic clamp which is optimal clamping tool for through hole drilling

and side machining on a large sized workpiece.

5-sided machining plate by a manual clamp

A manual clamp gets in the way of spindle accessanditmust be removed

and remounted every time one face is machined.

5-sided (4 sides + top face) machining is achieved only 1 time of

clamping operation, no need to remove or remount the clamp.

Number of jig change and Number of plate being completed

Mag clamp structure and function

Mold can be adhered and detached instantly(0.5-4.5 seconds).

Energization required only when switching on and off.

No energization required during clamped condition. No electricity consumed, thus no heat generation.

Clamp(Magnetized)

1.Electromagnetic coil is energized for 0.5 sec.

2.Polarity of alnico magnet is inverted.

3.Neodymium magnet and alnico magnet

become homopolar.

4.Magnet core becomes strong magnet

to adhere the workpiec.

Unclamp(Demagnetized)

1.Electromagnetic coil is energized for 0.5 sec.

2.Polarity of alnico magnet is inverted.

3.Magnetic flux of neodymium magnet and alnico

magnet is not emitted from the surface of the

magnet core so that the workpiece can be

unclamped.

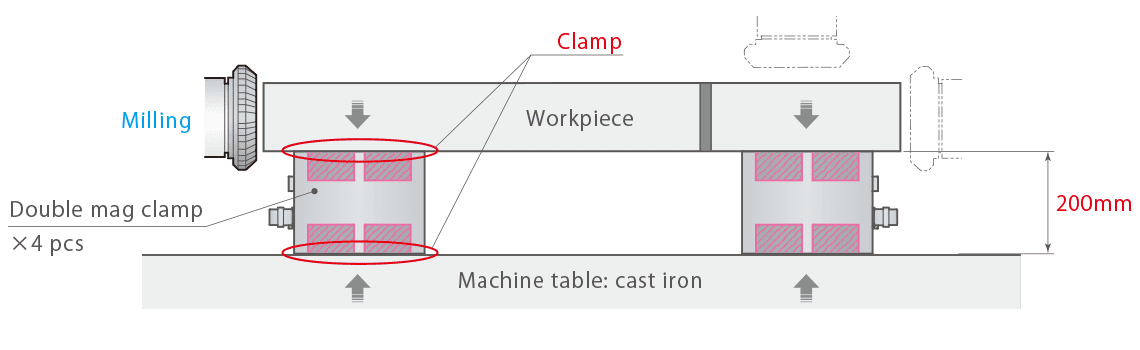

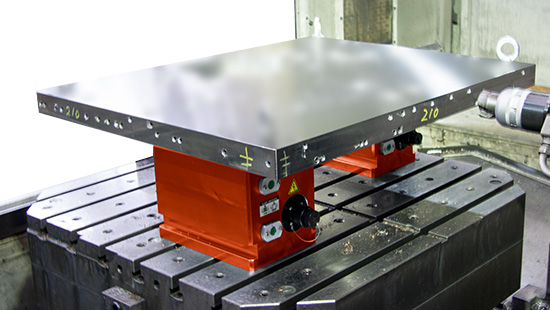

Practical example of double mag clamp

Machining machine for five-sur face

Double mag clamp × 4 pcs

Double mag clamp × 6 pcs

Double mag clamp × 4 pcs

Horizontal machining center

Double mag clamp × 2 pcs

Gun drill machine

Double mag clamp × 4 pcs

Install double mag clamp and drilling/ milling

Videos

VIDEO

Double mag clamp

mounting,

processing example

VIDEO

Double mag clamp

Practical example

Block workpiece

VIDEO

Double mag clamp

Practical example

Plate