MENU

Square core mag clamp MGA

(Magnetic clamp)

13,000kN

injection mold machine magnet clamp

Easy

die change

Instantly

clamps with strong permanent magnets (Neodymium・

Alinco Magnet)

Pascal Mag Clamp (Magnet Clamp) adheres the mold with strong magnetic force ・It is a mold clamp system for injection molding machines. Clamps instantly with the push of a button (0.5.-4.5 seconds). Energy is only required when turning On/Off (Clamp/Unclamp), no power is consumed and no heat is generated during mold clamping.

Clamp

(Magnetized)

- Electromagnetic coil is energized for 0.5 sec.

- Polarity of alnico magnet is inverted.

- Neodymium magnet and alnico magnet become homopolar.

- Magnet core securely clamps the mold.

Clamp

(Demagnetized)

- Electromagnetic coil is energized for 0.5 sec.

- Polarity of alnico magnet is inverted.

- Magnetic flux of neodymium magnet and alnico magnet is not emitted from the surface of the magnet core so that the mold can be unclamped.

Mold misalignment

detection system

Pascal’s

mag clamp can detect mold misalignment by using the electromagnetic coil built

into the magnet core near the center of the clamp plate. (When the mold moves,

the magnet coil’s generated power signals detection.)

When

the mold is misaligned → the induction current is generated.

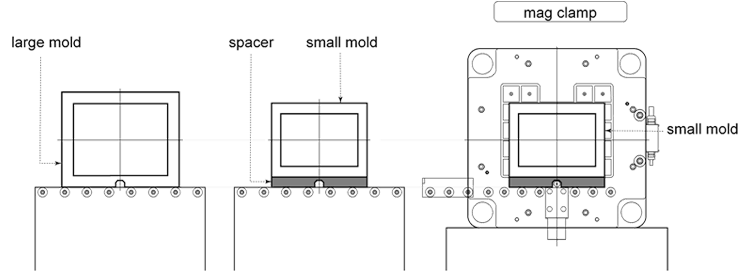

Mold size unification not necessary

It is

not necessary to unify the mold size. (vertical, horizontal, thickness)

Even if the mold height isn’t unified, by simply adjusting the load level, horizontal loading is possible.

With a mag clamp you only need a spacer.

Maximizes the mold’s machining surface

Because the clamp does not require mounting space, it maximizes the

mold’s machining surface.

With a

hydraulic air clamp, clamp mounting space is necessary.

The core cylinder,

battery connector, coupler, hose, and other interferences can be a problem.

| Product | Model | Catalog |

| Square core mag clamp | MGA |

| Option |